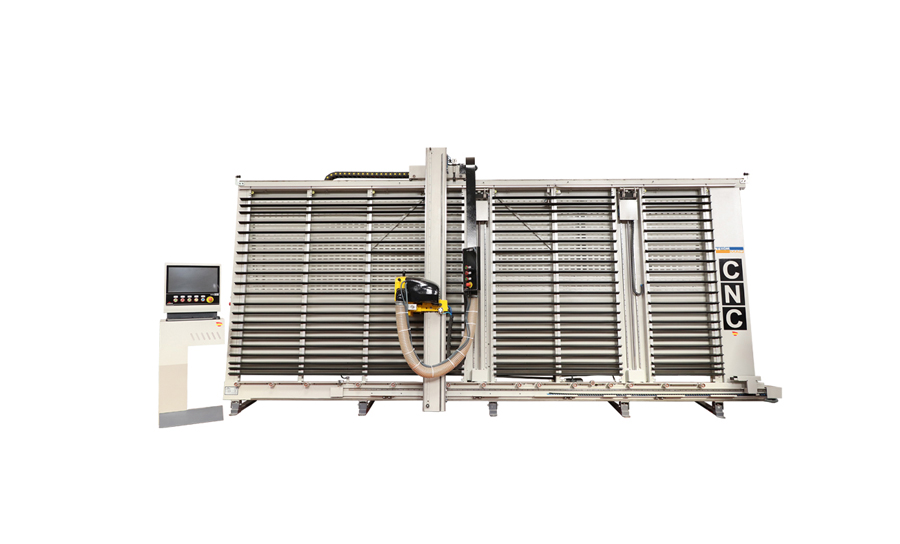

The Tec-Maq range of vertical saws halves the area required compared to other cutting machines, making it ideal for environments with space limitations. These vertical saws are available at Gimeno Woodworking machinery in different models, with a price from 21.450€ to 93.170€.

Vertical saw Tec-Maq range: models

The characteristics of the different models of the Tec-Maq range of vertical saws that we offer are specified below:

- Tec-Maq E. Max. working height 2100mm, max. working width 4100mm, with retractable grill, workpiece thickness 0-60mm, with main blade and scoring blade, and optional angle gauge.

- Tec-Maq N. max. working height 2100mm, max. working width 4100mm, with retractable grid, workpiece thickness 0-60mm, with main disc and scoring unit, with sliding rollers, and optional angle gauge.

- Tec-Maq NF. Max. working height 2100mm, max. working width 4100mm, with retractable grill, workpiece thickness 0-60mm, with main and scoring blade, with sliding rollers and angle gauge.

- Tec-Maq P. Max. working height 2100mm, max. working width 4100mm, with retractable grid, workpiece thickness 0-60mm, with main disc and scoring unit, with sliding workpiece rollers, angle gauge, vertical table sliding: clamps.

- Tec-Maq CNC: max. working height 2100mm, max. width 4100mm, with retractable grill, workpiece thickness 0-60mm, with main disc and scoring unit, with sliding workpiece rollers, angle gauge, vertical table sliding with clamps, horizontal table sliding with movable clamp.

Each of these models is designed to adapt to the needs of all types of production lines requiring a compact vertical saw with high performance, ease of use and durability.

Vertical saw for wood: Tec-Maq range technical features

The Tec-Maq range of vertical saws stands out for the quality of its components and its high technological features:

- Cutting unit. It includes a cutting unit with main blade and scoring unit, both driven by a single motor, and the adjustments are made by means of integrated levers. Safety is guaranteed by a micro switch that stops the discs if the group protection is open.

- Cutting head displacement. The cutting head moves manually in a vertical direction along 3 guides positioned on a sturdy bridge. This bridge, with 5 anchorage points, is supported and moves horizontally on the machine. It is locked by pressing a foot pedal, which secures the bridge in place.

- Frame. The monobloc frame guarantees robustness and resistance to torsion, ensuring the parallelism of the upper crane rail and the roller support bar, supporting the weight and displacement of the cutting bridge.

- Control panel. The control panel, located to the right of the cutting unit, is designed for easy operation and includes a switch-on indicator light, start/stop buttons for discs, emergency button, height display, clamp activation and manual clamp adjustment buttons.

- Retractable grill. The front panel of the machine consists of 18 horizontal workpiece support rails. An automatic system detects and adjusts the position of the guides to avoid overlapping with the horizontal cutting line.

- Stops. Stops with millimetric guides and a digital display for maximum precision in the measurement adjustments, facilitating the operator’s work.

- Workpiece support system. Composed of 18 high quality aluminium support wheels on the lower part, 4 of them equipped with plastic stops to ensure the positioning of the panels, as well as 4 flat support pieces also on the lower part.

- Support system for small workpieces. For cutting small workpieces, more machines are equipped with a cylindrical longitudinal guide and multiple support supports for short workpieces.

- Clamps for clamping the panels. Tec-Maq P and Tec-Maq CNC vertical saws are equipped with a panel clamping system, allowing the user to adjust the panel vertically to cut small workpieces without the need to repeatedly load and unload the panel.

- Board sliding system. The Tec-Meq CNC vertical saw incorporates a clamp system at the bottom for automatic movement of the board along the grid, positioning the board with the same precision as the measurement entered in the machine’s cutting program.

- CNC control panel. The Tec-Maq CNC vertical saw is programmed and controlled from a complete panel that includes a CNC, a computer and start and emergency stop buttons, allowing the automatic execution of the cutting programs without operator intervention.

If you are interested in finding out more about the Tec-Maq range of vertical saws, please contact us and GIMENO’s specialist woodworking machinery technicians will advise you on how to increase the performance of your production line.