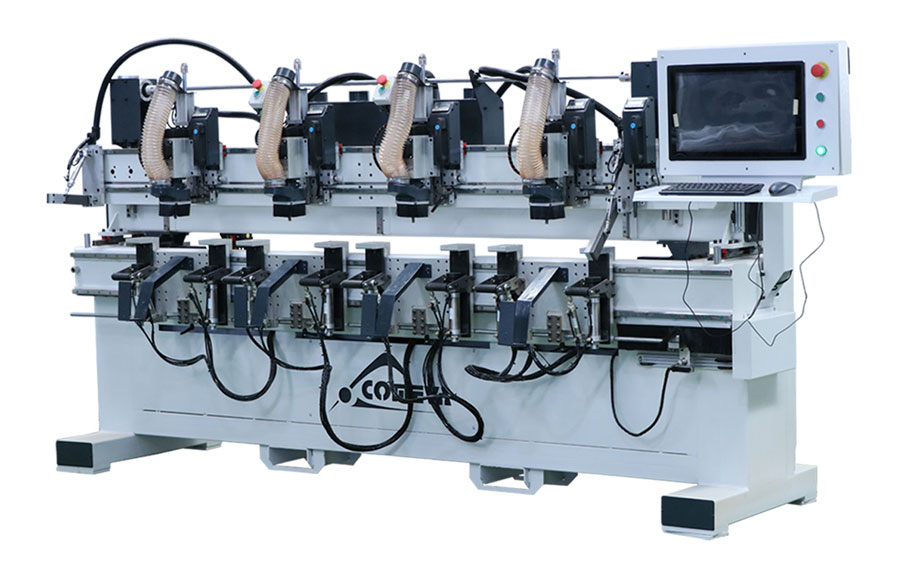

Comeva’s Cube edge bander machines, are available at GIMENO official distributor of the main brands of woodworking machinery. This edge bander is a high quality and robust machine that offers an unbeatable finish.

Comeva’s range of Cube edgebanders is characterised by the excellence of precision and speed in each job. This compact edgebander is specially designed for the edging of pieces, offering great ease of adjustment and finishing quality.

Comeva’s Cube range of wood edgebanders: models and technical features

The feeding system is composed of high-grip shoes and an upper system of rubber wheels to press on the workpiece. This system fixes the workpiece during the process, guaranteeing maximum stability and precision in its movement and edging.

The gluing unit includes the glue tank and regulator, thermoregulated for temperature, and pressure roller for gluing the edge. In addition, it has an edge guiding and cutting system, and automatic loading of edges in rolls by means of the side plate.

The machines are equipped with a touch screen for optimum operator control, including an automatic digital thermostat to control the glue temperature, as well as start/stop buttons for the different groups. All controls are simplified and located on the front for easy access.

- Cube: drag chain, gluing unit and profiling unit.

- Cube 2: drag chain, gluing unit, trimming unit and profiling unit.

- Cube 3: drag chain, gluing unit, trimming unit, profiling unit and polishing unit.

Comeva’s Cube range of wood edge banders: working groups

The end cutting unit has a 0.37 kW motor with double output and two cutting discs. It moves along linear guides with detectors on the piston to cut the excess veneer on the front and back of the piece (group incorporated in the Cube 2 and Cube 3 models).

The trimming unit of the machines has two 0.37Kw high frequency and independent motors, each equipped with a milling cutter for top and bottom edge profiling. In addition, it includes horizontal and vertical copying devices to align the tools to the working point, allowing the excess edge to be trimmed on both the upper and lower sides.

The machine’s polishing unit is equipped with two 0.18 kW tilting motors, one upper and one lower, each with cloth polishing discs. These motors clean the edges of any glue residue and also polish or buff the edge to obtain an impeccable finish after the gluing and profiling of the board (incorporated in the Cube 3 model).

The veneer machines in the Cube range are designed and manufactured in Spain by Comeva’s specialist woodworking machinery technicians. Contact us for full details and advice on how to increase the performance and profitability of your production line.